Barcode Grader And Barcode Grading: Things You Should Know

How can you check if your printed barcode will scan anywhere if you need to be certain?

A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can be read by that specific scanner.

Keep reading to find out more about barcode grading and barcode grader.

What is a barcode grader?

What Is A Barcode Grader?

A barcode's scannability can be assessed using its grade.

A barcode grader, sometimes referred to as a barcode verifier, will evaluate numerous variables or criteria.

An A–F scale is used for the ANSI grades.

A symbol's overall grade serves as a pointer to the readability of a symbol. These factors are rated in 10 different cross-sections of the code.

You may follow the computation of the final barcode grading back to the specific parameters of each scan using the detailed data provided by webscan verifiers for each scan cross-section.

For instance, a code may receive a B grade if it scores well in 8 out of 9 parameters.

However, the overall grade will reflect the worst-case scenario of a F if one section continuously receives an F.

The overall barcode grade is calculated by averaging the results from all 10 scans.

Thus if 5 scans receive A grades and 5 scans receive F grades, the total grade will average out to a C.

A barcode grader

Why Should You Use A Barcode Grader?

The correct barcode verifier will save you time and give you trust in your barcoded goods if your company manufactures any form of barcode on any type of product.

Using a barcode validator, or barcode checker as some prefer to call it, that complies with industry standards, is the only method to ensure that your codes are compliant with regulations and are successfully printing and scanning.

The greatest barcode grading solutions are made possible by Webscan's barcode verification software and premium optics.

It helps:

-

Decrease product returns

-

Lessen packing waste and costs

-

Save time by preventing expensive reprints and/or reships

-

Ensure that the requirements of the contract and the industry are met.

Barcode tester

How Does Barcode Grading Work?

Since the initial American and European standards, ANSI X3.182 and EN 1635, were originally published in 1990 and 1995, respectively, international standards have been developed for measuring and rating the printed quality of barcodes.

The most recent ISO/IEC standards outline the procedures necessary for both traditional linear barcodes and two-dimensional barcodes.

Seven different characteristics of the barcode will be measured by a linear barcode verifier are:

| Criteria | Explained |

|---|---|

|

Symbol contrast |

How monochromatic it appears to a scanner |

|

Minimum reflectance |

Whether the dark bars and the white areas differ sufficiently |

|

Edge contrast minimum |

The smallest distinction between a space and a bar |

|

Modulation |

Varying amounts of black and white contrast are present throughout the barcode |

|

Defects |

The presence of light or dark marks in the spaces or white marks within the bars |

|

Decodability |

How precise the various bar and spacing lengths of the barcode are |

|

Decode |

Whether the data encoding, light margins on each side, and check digit are all accurate |

A barcode's total grade, which ranges from 4.0 to 0, is determined by the results of this testing.

4.0 is the best score, 1.5 is considered a pass for most barcodes, 0.5 is acceptable for outer case barcodes printed on brown corrugated paper, and 0 indicates a failure.

A pass grade of 1.5 or C is frequently necessary because the American ANSI standard was designed using an alphabetic grading system that runs from A to D, then F.

| ISO/IEC grade | ANSI grade |

|---|---|

|

3.5 - 4.0 |

A |

|

2.5 - 3.5 |

B |

|

1.5 - 2.5 |

C |

|

0.5 - 1.5 |

D |

|

0 - 0.5 |

F |

Read also: Facebook QR Messenger quick

Barcode Grading Parameters

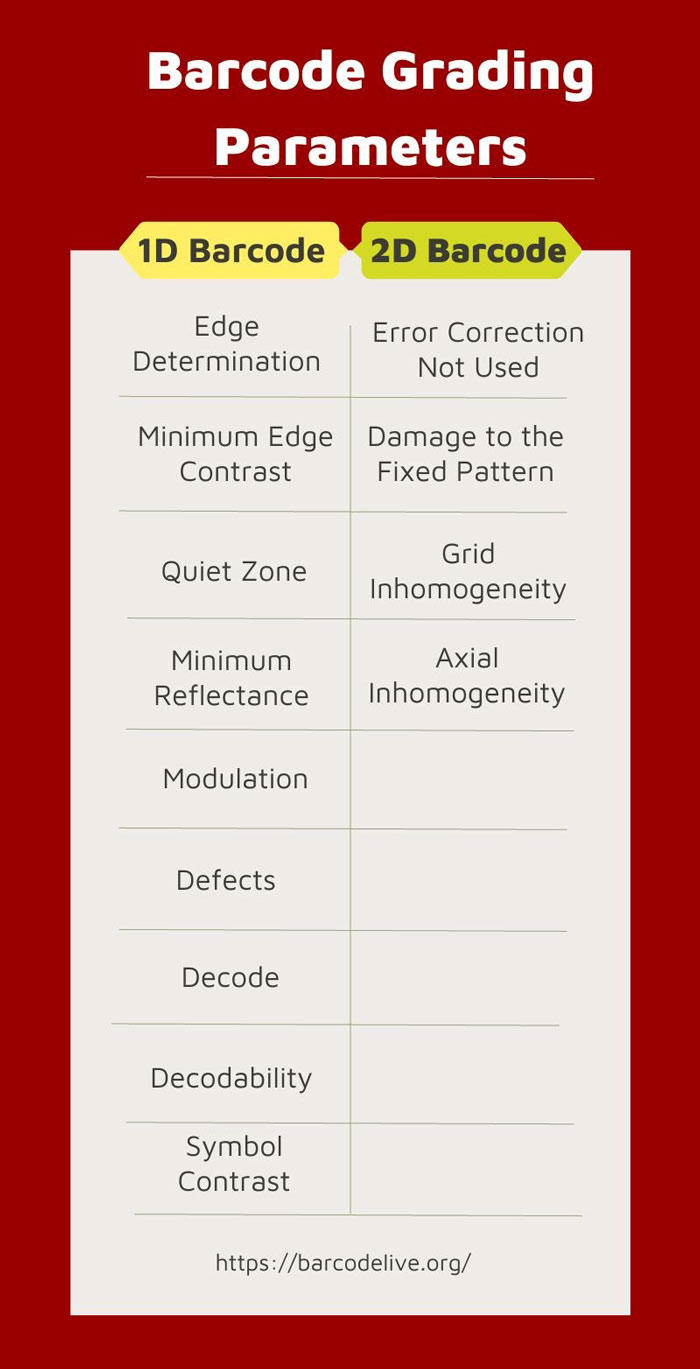

The symbology affects the characteristics that a barcode grader measures.

For instance, according to ISO/ANSI regulation, verifiers for 1D linear barcodes should verify 9 quality parameters.

Barcode grading criteria

Similar steps and criteria apply to multi-row stacked barcode grading, with the exception that the criteria will be assessed for each row of the symbol.

Additionally, Unused Error Correction will be present if the stacked symbol contains error correction.

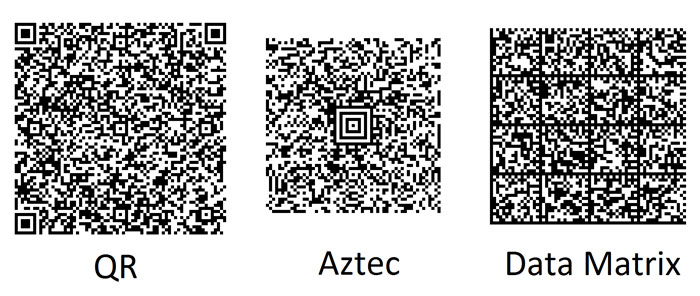

Several barcode grade characteristics are different for 2D matrix symbols.

2D Barcode

The barcode grader's parameters for modulation and contrast of symbols are comparable to those for 1D linear codes.

Except that the modulation grade computation differs in that it considers the presence of error correction in the 2D symbol.

Read also: Generate ISBN barcode

What To Do If You Receive Failing Grades?

The user can view a complete detailed report if the verification software indicates that the symbol failed.

The findings of each of the 10 separate scans will be shown, and each parameter will receive a grade.

Here, you can examine the parameters where the barcode failed and determine how to correct the issue for upcoming print runs.

For a thorough understanding of the reasons for low grades for each criteria, consult the ANSI/ISO Quality Parameters.

You can modify your production process to enhance that feature of the code depending on the specific parameter that led to the failure.

What to do if you receive failing grades?

When picking a barcode grader, several factors must be taken into account.

For the items you are verifying, you must determine the field of vision, minimum x-dimension, illumination angle, format, and software requirements.

Simply said, thorough verification will guarantee that the barcode can be read by all parties involved in the supply chain.

It can allow for quick, accurate inventory and the transfer of goods from manufacturer to distributor to retailer to ultimate consumers.

Barcodes of poor quality can lead to lost productivity, shipping returns, and exorbitant fines.

You can be confident that your printed barcodes will be recognized by any scanner by making sure they adhere to compliance guidelines.

In order to create readable, high-quality codes, producers follow barcode verification's marking instructions.

Verifiers of barcodes evaluate them and give them a quality rating, which is commonly stated as an A through F letter grade or a number equivalent (4 to 0). A passing barcode is one that is 100% scannable and has a grade of C or higher.

Conclusion

Incorrect barcodes have the potential to disrupt the supply chain and will be traced to the barcode manufacturer. Additionally, the firm will be better able to meet the demands of a diverse consumer base if it is able to adhere to a set of requirements and standards. So, for producers of barcoded products, barcode grading using a barcode grader is a crucial step.

Follow Barcodelive to get further interesting information about barcode.

![Barcode Sizes Explained & FAQs: An Ultimate Guide [The Latest]](https://barcodelive.org/filemanager/data-images/imgs/20221031/Barcode-Sizes-Tutorial_1.jpg)

11 Comments

Patricia Williams

This is great stuff

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

Glad you liked it

Leave a Comment

Your email address will not be published. Required fields are marked *Benjamin Thomas

What is 2D barcode verifier?

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

The system uses a special array of LEDs and a CCD-based sensor to capture each barcode image before it is analyzed

Leave a Comment

Your email address will not be published. Required fields are marked *Benjamin Thomas

Ok, I got it now. Thank you

Leave a Comment

Your email address will not be published. Required fields are marked *Melissa Baker

Thank you for the great guide

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

No problem

Leave a Comment

Your email address will not be published. Required fields are marked *Alaya Wright

What is modulation in barcode grading?

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

It refers to localized issues with contrast, meaning that certain spots within a code are not displaying enough contrast

Leave a Comment

Your email address will not be published. Required fields are marked *Talia Hill

Long but very informative and to the point guide. I think you have covered all the aspects from every possible angle

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

Thanks

Leave a Comment

Your email address will not be published. Required fields are marked *Leave a Comment

Your email address will not be published. Required fields are marked *