Barcodes Standards: A Complete Explanation [Updated 2023]

There are several barcodes standards relating to how to decode it, barcode size, how a data put into a barcode, etc.

All they are created by the International Organization for Standardization (ISO).

Depending on these standards as well as their uses, types of barcode have different application.

Reading the article to get more details.

Understand barcode standards

About Barcodes Standards

With such a wide range of barcode symbologies and uses, businesses and organizations in all over the world are constantly producing barcodes.

However, when commodities move through the supply chain and parts and products move from one firm to the next, consistency is required to simplify the flow of information.

That is why standards are created.

Barcode standards

According to AIM (Automatic Identification and Mobility), there are three types of barcodes standards: official, ad hoc, and de facto.

However, for the purposes of labeling parts, products, and items, the discussion focuses on official standards that are sanctioned by an accredited standards body.

Technology standards explain how things operate, but application standards define how a technology is utilized rather than how it works.

What Are ISO Barcodes Standards?

ISO bar code standards

ISO stands for International Organization for Standardization.

It indicates that ‘A standard is a document that provides requirements, specifications, guidelines or characteristics that can be used consistently to ensure that materials, products, processes and services are fit for their purpose.’

There are hundreds of ISO standards, some of which apply to barcodes—how data is encoded in a barcode, how to decode it, how to calculate the size of the barcode, and so on.

There are just three ISO standards that address barcode quality.

These three typical standards are:

-

ISO 15416 for 1D barcodes

-

ISO 15415 for 2D label-based barcodes

-

ISO/IEC TR 29158, or AIM DPM for 2D DPM codes

We will discuss all in details in the following parts!

What Are Types Of ISO Barcodes Standards?

As mentioned earlier, there are only 3 types of ISO barcodes standards relating to barcode quality. Reading the article to understand more about them.

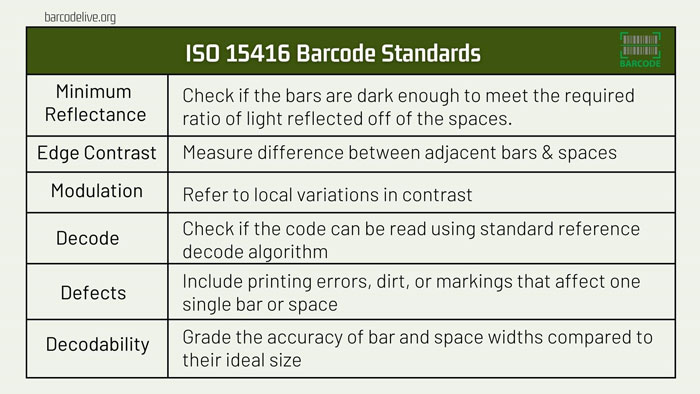

ISO 15416

This ISO standard for 1D barcodes requires 10 distinct scan lines to be captured across the height of a code, with a grade assigned to each scan line.

Many variables influence scan line grades.

If a scan line fails minimum reflectance, decoding, or minimum edge contrast, a "F" grade is automatically assigned.

If all three pass, the program ranks the parameters of symbol contrast, modulation, flaws, and decodability.

Each is rated from A to F. After grading each scan line, the ten scans are summed to produce a formal grade for the barcode.

ISO 15416

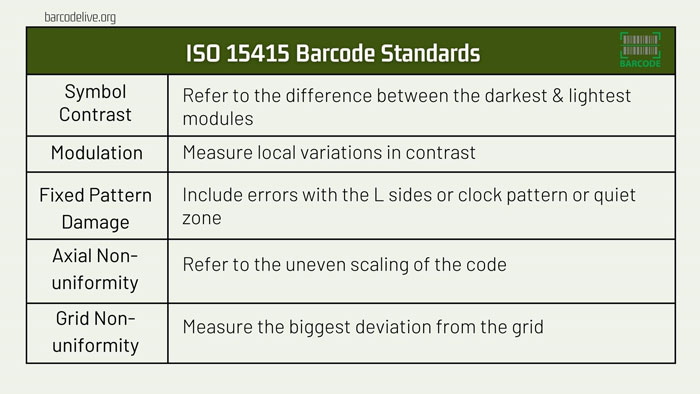

ISO 15415

This standard evaluates 2D barcodes based on eight separate criteria.

The lowest individual rating becomes the code's total grade.

The grading procedure begins with a pass/fail test. If the code can be decoded, the first condition is passed.

If it cannot, it is automatically given a "F." Some questions to ask to discover the cause of a no-decode include:

-

Are you using the proper aperture, ISO, and lighting angle?

-

Is the symbology turned on? Is the camera focused?

-

Is the code in the center of the screen?

-

Is the size of the cells proportional to one another?

-

Is every component of the finder pattern present?

After decoding a code, the following parameters are assessed.

ISO 15415

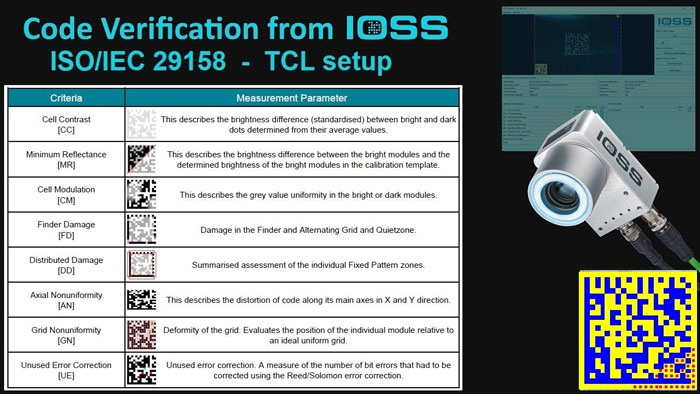

ISO/IEC TR 29158

With a few key differences, the quality parameters and grading process for DPM codes are similar to ISO 15415.

The first is the method by which the global threshold is determined.

The global threshold is the dividing line between light and dark cells.

The location of that line is critical because it determines whether a cell is closer to light or dark.

AIM DPM calculates global threshold using a more sophisticated algorithm than ISO 15415 to accommodate a wide range of background surfaces.

AIM DPM also supports 30-, 45-, 90-degree, and dome lighting.

This allows for verification of curved, reflective, or dot peen-marked parts.

ISO/IEC TR 29158

Some industry committees have also created application standards that specify which ISO standard to grade against.

Medical device, retail, transportation, food service, and the US Department of Defense are among these industries.

See also: Barcloud ASAP

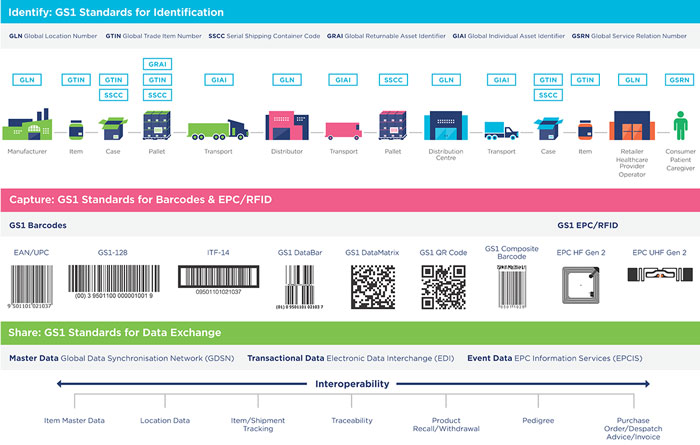

What Are GS1 Barcodes Standards?

GS1 is the barcode standards used by retailers, manufacturers, and suppliers.

In 1974, the barcode was invented by GS1 which is a global, non-profit standards group with over one million members that seeks to achieve agreement that assists enterprises in transferring important data.

To facilitate worldwide collaboration, GS1 specifies general as well as particular bar code standards for identification, data collection, exchange, and usage.

GS1 specifies standards for identification, data collection, exchanges, and usage

What Barcode Types Does GS1 Set Standards For?

The following is a list of the barcodes and other identifiers for which GS1 establishes standards:

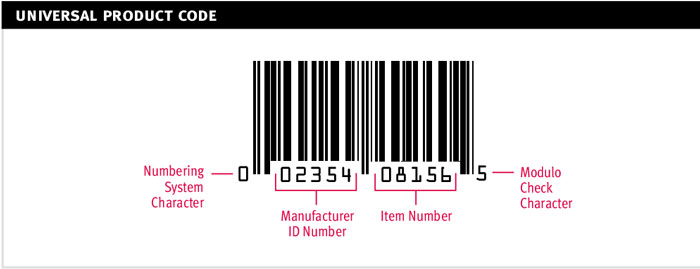

EAN/UPC

According to the association, the EAN/UPC family is the oldest and most frequently used GS1 barcode standard.

This type of barcodes has become so popular in retail products.

EAN barcodes include 13 digits (which are also encoded in the barcode), whereas UPC barcodes have 12 digits.

EAN/UPC Barcode

There is significant disagreement over the role of GS1 in developing the EAN and UPC standards, particularly regarding nation coding for the United States and Canada

Also, the quantity and value of the identification numbers encoded in the bars and in human-readable digits in each standard have several dispute.

In general, EAN barcodes employ the additional digit to show the nation that issued the ID, whereas UPC did not at first, owing to the fact that North American supermarkets carried few foreign items and sometimes had outdated equipment that could not detect more digits.

The UCC mandated enterprises in the United States and Canada to modify their systems by 2005 so that they could scan and handle EAN codes.

DataBar

GS1 DataBar, another prominent barcode standard, is a smaller, more information-dense barcode format that is extensively used to mark fresh commodities.

It can encode expiry dates, batch numbers, and other data that may be used to trace a food's trip through the supply chain.

The seven GS2 DataBar kinds are separated into labels meant for POS barcode reader or scanner systems and other labels used in distribution and logistics.

DataBar

1D barcodes

One-dimensional (1D) barcodes are also used in distribution and logistics applications.

They are frequently printed directly on the corrugated boxes used to ship retail merchandise.

If the retail products in each box are all the same, certain versions can additionally encode the UPC code.

1D barcodes can also be used to designate finished goods that aren't sold in stores.

1D Barcode

See also: Barcode Identifiers: Everything You Need To Know [FAQs]

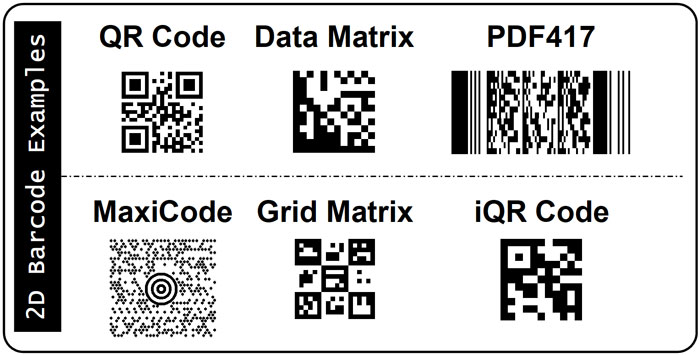

2D barcodes

Unlike the lines found in EAN/UPC barcodes, two-dimensional (2D) matrix barcodes are squares or rectangles with little dots.

It likes DataBar which includes traceability capabilities including the ability to identify manufacturing batches or lots, as well as expiration dates.

They may be etched directly into goods using a variety of techniques, including chemical etching and laser etching.

2D barcodes

2D matrix barcodes are classified into two categories.

DataMatrix barcodes are commonly seen on little things such as vials of medicine, but they are also found on printing materials such as letters.

DataMatrix barcodes can be as tiny as a millimeter or as large as a yard wide.

The Quick Response (QR) code is a 2D barcode that is becoming increasingly popular since it can hold significantly more information than conventional barcodes.

QR codes have become commonplace in advertising and marketing materials, allowing smartphone users to access web-based product information.

EPC

GS1 also monitors a standard for the Electronic Product Code (EPC), a syntax for unique ID numbers developed by researchers at the Massachusetts Institute of Technology Auto-ID lab.

The EPC is a method of putting barcode information on RFID tags and of transferring data between corporate systems.

EPC

The EPCglobal standard is also lauded for boosting supply chain visibility and efficiency by making it easier to trace inventories along the supply chain, which can reduce missed revenues due to stock outs.

EPCglobal may increase the traceability of goods from manufacture to final destination, reducing tampering, counterfeiting, and breaches of environmental laws and other compliance requirements.

Verifiers will use worldwide bar code standards to determine how well a barcode will operate in various circumstances.

It will identify where the code is inadequate so that corrective action may be taken.

Verification compares the optical features of the barcode to international and industry standards.

Based on these characteristics, the barcode quality is assigned a pass or fail rating.

True verifiers compare the features of a code to barcode standards such as ANSI X3.182, ISO/IEC 15415, and ISO/IEC 15416.

The top barcode verifiers adhere to ISO/IEC 15426-1 and 15426-2 criteria of accuracy.

While there is no single standardized barcode format, there are a few key specifications that govern how they are designed and created.

Size, capacity, linearity, material, and whether or not a checksum is required can all vary between barcode labels.

The size of a label is frequently determined by the scanning equipment specifications and the intended application.

A specific label orientation may be required in some cases to accommodate scanning hardware or other process equipment.

A UPC symbol must be created within the permitted size range in order to be scannable.

There was a claimed "standard" size UPC barcode termed 100% magnification when the UPC rules were first released.

A 100% UPC has total dimensions of 1.46′′ x 1.02′′. UPC magnifications have a size range of 80-200%.

Compliance with GS1 does not have to be as difficult as reading the 534-page GS1 General Specifications.

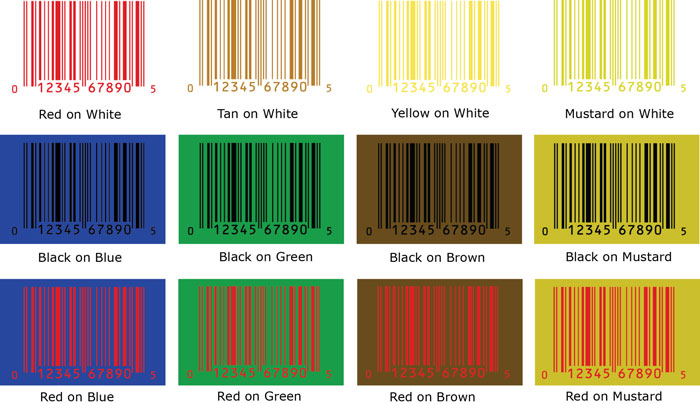

While these supplementary charts/tables help with UPC color, many elements of UPC barcoding and product data management need a much larger resource.

Conclusion

To sum up, we hope you found this post useful in providing information about barcodes standards. By identifying the correct type of barcode, you can now know how it can be applied to your business.

![Barcode Sizes Explained & FAQs: An Ultimate Guide [The Latest]](https://barcodelive.org/filemanager/data-images/imgs/20221031/Barcode-Sizes-Tutorial_1.jpg)

11 Comments

Gary Moore

What do the digits on a barcode mean?

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

They are a human readable representation of the barcode in case it cannot be scanned

Leave a Comment

Your email address will not be published. Required fields are marked *Angela Thompson

What is ANSI Grade C?

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

A rating of a “C” means that a barcode will scan on virtually any machine, so many product packagers require this rating on their products

Leave a Comment

Your email address will not be published. Required fields are marked *Mary Kelly

Your article is great, but I still want to ask you a question: Are GS1 and EAN the same?

Hope you will answer

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

EAN/UPC barcodes are printed on virtually every consumer product in the world. They are the longest-established and most widely-used of all GS1 barcodes

Leave a Comment

Your email address will not be published. Required fields are marked *Samuel Scott

Is GS1 same as UPC?

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

The major distinction between these two is that GS1 Company Prefix has a zero added to the beginning of the number

Leave a Comment

Your email address will not be published. Required fields are marked *Eric Kim

Who used GS1 barcodes?

Leave a Comment

Your email address will not be published. Required fields are marked *Barcodelive

You may find GS1 barcodes on a multitude of products across industries like retail, healthcare, transportation, and logistics

Leave a Comment

Your email address will not be published. Required fields are marked *Eric Kim

Thank you

Leave a Comment

Your email address will not be published. Required fields are marked *Leave a Comment

Your email address will not be published. Required fields are marked *